This is the shed sitting in front of my house on the delivery truck. We load them with a forklift using fork extenders. You can pick up a bigger load but not a heavier one. The shed is 12' long and the bed of the 97 GMC is 16'. We load the sheds so that they are about 6" past center on the bed. For this trip, my workman Matt Zaijcek and my sister Kerry were along to help with the delivery and to do the photo shoots.

Here is me driving and Matt standing in the background. The truck is all lined up and in position. We're ready to dump us a shed!

Up she goes! The shed appears real close to the forklift (right side of photo) but in reality there was a good 3 feet or so between the shed and lift. I'm used to squeezing in places with less than 6" on either side if need be.

The shed has just now touched the ground. We're ready to lock in the e-brake and remove the straps that hold the shed onto the bed.

Notice the straps have been removed and I've pulled forwards until this is just about 12" to 18" of shed left on the bed. At this point I'm ready to pop the clutch in 2nd gear and get out of the way. If I drive slow, the shed falls into the bed and does things like rip doors off of hinges, splinters siding, and all horrible manner of things. (Don't ask!)

Notice the bed of the truck on the left side of the photo. I've pulled out and successfully dumped yet another shed. That's Matt Z. getting ready to grab the tool and set the shed on blocks. The job is only beginning at this point!

And of course, here is me NQ (Erin Lassley) showing off my skills in flagrant fashion. I do owe half of the kudos to my riders because they are my eyes when I'm backing up and signal me when to stop raising the bed. I can't do these shed dumps myself and quite frankly I'm only 1 of 2 guys who will even attempt this. My workmate John Malchow will do it but doesn't like to if he can get out of it.

This is me again with my sister pressing down on the pipe we use for a lever to lift these sheds up so we can get blocks under them. Notice how the pipe is bending down from the weight of the shed. It's taking both of us just to hold the shed up in the air (see my knees and hands are both on the pipe). Matt stopped a minute under my prodding to take this photo. He ultimately was the one who put the blocks under the shed and he did a real good job of it too. Thanks Matt!

And here we are, Erin Lassley and Matt Zaijcek. The shed is on blocks and the delivery is done. This was Matt's last year to work at the lumber yard as he is a 4th year college student. I'm really going to miss working with him - he was a great guy to work with! He left for school in Mid August and I think these photos were shot in late June of 99.

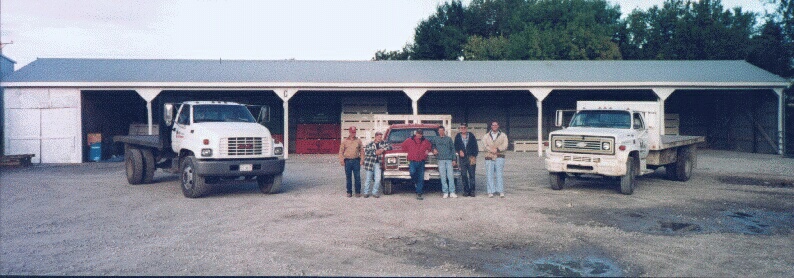

I added this photo after the original page detailing the shed delivery was constructed. This is our yard crew at Mead Lumber as of the first week of October of 1999. From left to right we have John Malchow, Brian Eppens, Todd Howell, Dustin Dreesen (fired), Harlan Parde (master of shed building with crooked lumber), and me Erin Lassley aka No Quarter. The trucks are a 1997 GMC with 16' bed, 1984 Dodge Ram with 12' bed, and a 1979 Chevy C60 with a 16' bed. In the background is our waferboard and sheetrock in what is known as the 'sheetrock shed.'

NQ 10-11-99

UPDATE: It's funny how time changes things. Brian Eppens was fired, re-hired, and quit within a couple years after this photo was taken. Todd Howell moved on to a better paying job. Dustin was fired the next day. Harlan is still building his sheds! I'm no longer foreman in the yard and as of 04-02 I'm working in the Rental Department maintaining equipment. We've added one more truck (2002 GMC Pickup with tilt bed and duallies) and the shed in the background has been shortened up so that the newly purchased property is accessible.